Coolant Chillers

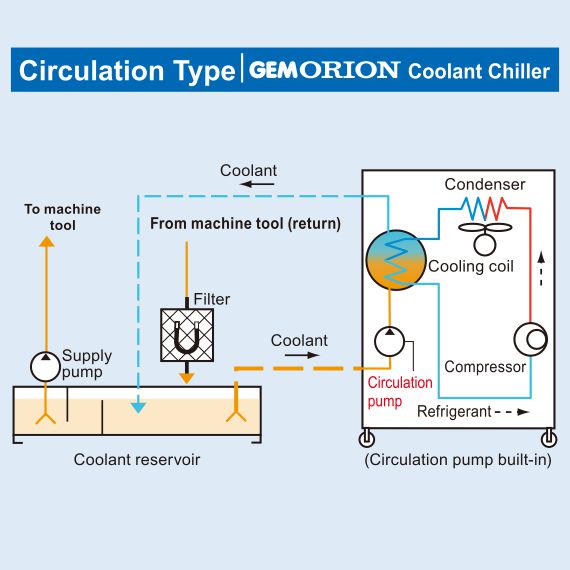

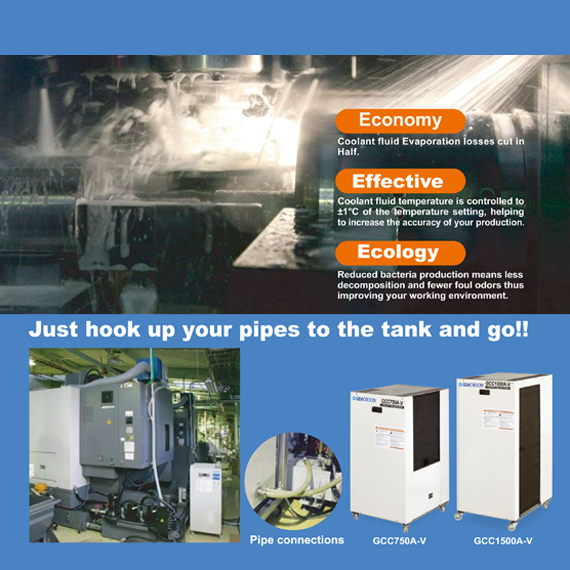

Coolant chiller (GCC 750/GCC 1500). Water-soluble metal working fluid temperature control for metal cutting and grinding applications. Coolant Chiller GCC Series is a well-built Air cooled chiller from Coimbatore based Gem ORION. We have effectively utilized Japanese technology to manufacture this sturdy and efficient equipment. Made to long-last, these water cooled chillers accomplish your unique requirements, especially in metal cutting and grinding applications.

We have established ourselves as one of the trust worthy Air cooled chiller manufacturers in India, thanks to the salient features we add to our chillers.