Heavy Duty Precision Chillers

Air cooled chillers with built in water tank. The performance of chillers depends on effective cooling. GKL series air cooled chillers effectively utilise Japanese technology to deliver the desired results. Heavy Duty Precision Chillers are advanced cooling systems engineered to maintain precise temperature levels in demanding industrial environments. These high-powered chillers come up with in-built water tank, which saves space and energy.

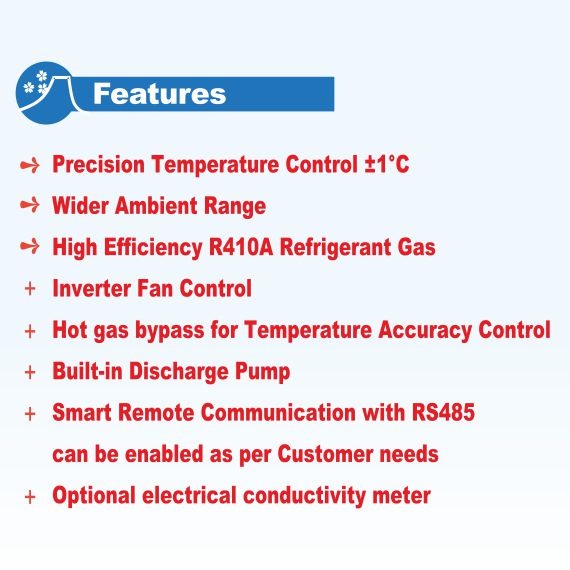

The GKL series chillers with built-in water tanks, pump already built into the unit, getting rid of cumbersome on-site piping installation usually required for closed loop systems. The unique features of GKL series have earned an unassailable lead for Gem ORION as an innovative air chiller manufacturer in India. This GKL series industrial air cooled chillers come up with multitude of benefits including wide operating range, efficient temperature control and so on.