Introduction

In plastic injection moulding, temperature control directly impacts product quality, cycle time, and machine efficiency. As industries advance toward smarter, energy-efficient production lines, the demand for Inverter Chillers has grown significantly.

At Gem Orion Machinery Pvt. Ltd., we offer advanced inverter chiller systems designed to optimize moulding performance while reducing energy consumption.

Why Temperature Control Matters in Injection Moulding

Injection moulding machines generate significant heat during continuous operation. If the mould temperature is not controlled properly, it can lead to:

- ✅ Warping or deformation of moulded parts.

- ✅ Longer cooling cycles and reduced productivity.

- ✅ Inconsistent product quality.

- ✅ Higher rejection rates.

- ✅ Increased mechanical wear and downtime.

A high-performance Inverter Chiller ensures the mould stays at the ideal temperature, resulting in smoother production and exceptional output quality.

What Is an Inverter Chiller?

An inverter chiller uses variable-speed compressor technology that automatically adjusts cooling capacity based on the actual heat load. Unlike traditional chillers that run at fixed speeds, inverter chillers offer:

- Intelligent power control

- Precise temperature stability

- Reduced energy wastage

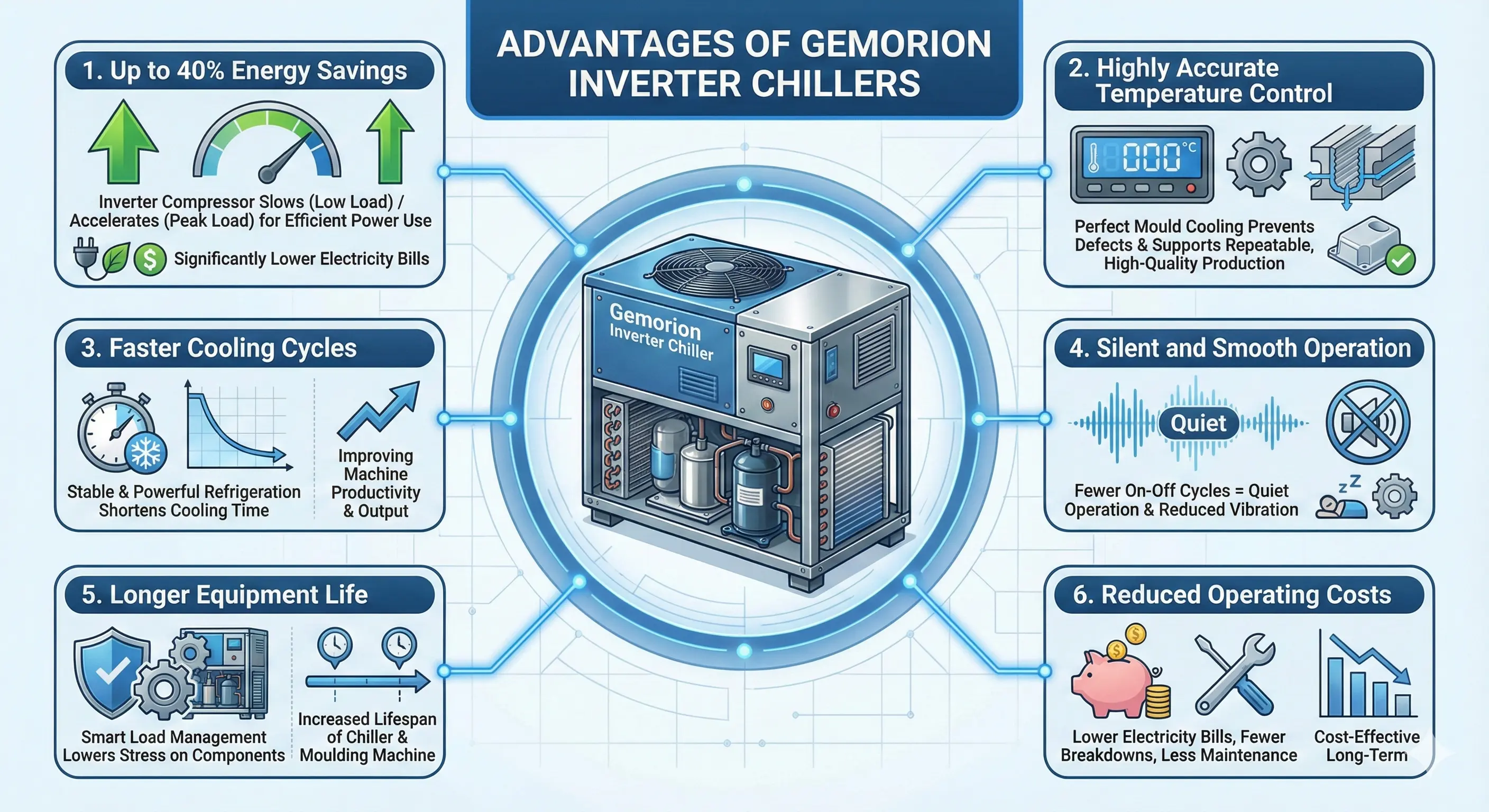

Advantages of Inverter Chillers

- Up to 40% Energy Savings

The inverter compressor slows down during low load and accelerates during peak load, ensuring efficient power use.

- Accurate Temperature Control

Perfect mould cooling prevents defects and supports repeatable, high-quality production.

- Faster Cooling Cycles

Stable and powerful refrigeration shortens cooling time, improving machine productivity and output.

- Silent and Smooth Operation

With fewer on-off cycles, the system operates quietly and with reduced vibration.

- Longer Equipment Life

Smart load management lowers stress on components, increasing the lifespan of both the chiller and the moulding machine.

- Reduced Operating Costs

Lower electricity bills, fewer breakdowns, and less maintenance make inverter chillers cost-effective long-term.

Where Inverter Chillers Are Used

Our inverter chillers are suitable for:

- ✅ Plastic Injection Moulding Machines

- ✅ Blow Moulding Lines

- ✅ Extrusion Plants

- ✅ Packaging & Thermoforming Units

- ✅ Industrial Cooling Processes

Why Choose Gem Orion Machinery Pvt. Ltd.?

At Gemorion, we combine engineering excellence with energy-efficient technology. Our inverter chillers are built to ensure:

- ✅ High accuracy with digital controllers

- ✅ Reliable performance in harsh industrial environments

- ✅ Easy operation and installation

- ✅ Robust engineering for continuous, 24/7 production

- ✅ Dedicated service and support from our expert team

Conclusion

An Inverter Chiller is not just a cooling device—it is a strategic upgrade for any plastic injection moulding facility aiming for higher productivity, lower operating costs, and improved product quality. Gemorion Machinery Pvt. Ltd. delivers inverter chiller solutions designed for today’s demanding manufacturing standards.

Contact Us Today

Ready to enhance your industrial processes with reliable and efficient cooling? Gem Orion Machinery is here to help. Contact us today for expert advice and customized chiller solutions tailored to your industry’s needs.

- 📍 Address: Avinashi Road, Arasur, Coimbatore - 641407, Tamil Nadu, India

- 🌐 Website: www.gemorion.in

- ✉️ Email: sales@gemorion.in

- 📞 Phone: +91-96007 49675