Why It’s Essential for Performance & Longevity ?

When it comes to high-performance laser cutting, precision is everything. But behind every clean cut, smooth edge, and flawless engraving lies a crucial—but often overlooked—component: the Precision chiller. At Gem Orion Machinery Pvt. Ltd., we understand how vital stable cooling is to the health and productivity of your laser systems. That’s why our precision chillers are engineered to deliver consistent, reliable temperature control for a wide range of industrial laser applications.

Why Laser Cutting Machines Need a Precision Chiller ?

Laser cutting generates intense heat at the source. Without efficient cooling, this heat can cause:

- ✅ Thermal drift and reduced cutting accuracy

- ✅ Burn marks or inconsistent output

- ✅ Frequent machine downtimes

- ✅ Shortened laser tube or laser source lifespan

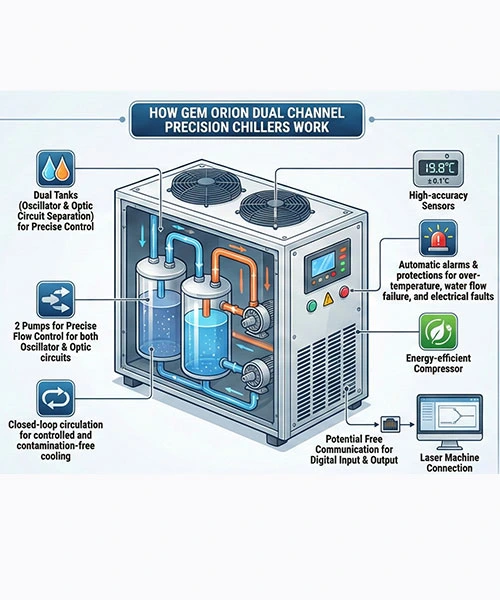

How Gem Orion Dual Channel Precision Chillers Work ?

Our chillers use advanced refrigeration and intelligent control systems to extract heat from the laser source and stabilize the internal temperature. Key functions include:

- Dual Tanks for separation of Oscillator circuit & Optic circuit, thereby precise control of both temperatures.

- 2 pumps for precise flow control for both Oscillator & Optic circuits.

- Closed-Loop circulation for controlled and contamination-free cooling.

- High-accuracy sensors for steady temperature maintenance.

- Automatic alarms & protection for over-temperature, water flow failure, and electrical faults.

- Energy-Efficient compressors designed for uninterrupted industrial use.

- Potential Free communication for Digital Input & Output that connects the chiller with Laser machine.

Key Benefits of Gem Orion Precision Chillers

- ✅ Enhanced Cutting Accuracy

Stable temperatures eliminate thermal expansion, ensuring sharper edges and consistent results

- ✅ Extended Machine Life

By preventing overheating, the chiller dramatically increases the lifespan of your laser source and internal components.

- ✅ Improved Productivity

No more unplanned shutdowns or performance drops—just smooth, continuous operation.

- ✅ Reduced Maintenance Costs

Less thermal stress means fewer repairs and replacements over time.

- ✅ Energy-Efficient Cooling

Our modern chiller systems consume less power while delivering superior cooling performance.

Applications Across Industries

Gemorion precision chillers are ideal for all laser systems, including:

- ➤ CO₂ Laser Cutting Machines

- ➤ Fiber Laser Cutting Machines

- ➤ Laser Engravers & Markers

- ➤ CNC and Industrial Automation Units

Why Choose Gem Orion Machinery Pvt. Ltd.?

We bring engineering expertise, reliable support, and a commitment to innovation. Our chillers are built for Indian industrial conditions, combining durability with precise performance. Every unit comes with:

- ✅ Robust construction

- ✅ Easy installation

- ✅ Smart digital controls

- ✅ Long-term service support

Conclusion

A precision chiller is more than an accessory—it’s a critical investment for any laser cutting setup. By choosing a Gem Orion Precision Chiller, you ensure your laser machine operates with maximum accuracy, safety, and longevity.

For product details, technical specifications, or installation support, contact Gem Orion Machinery Pvt. Ltd. today and keep your laser systems running at their best.